Set Up Back-to-Back Transfer Flow

The topic explains what you need to do for setting up back-to-back transfer flow.

In the Oracle Product Information Management, ensure that the Item is Back-to-Back enabled.

In Oracle Global Order Promising:

1.Set up a global sourcing rule with Type as Transfer from. Set the organization as the organization requesting the transfer (example, Warehouse 1).

2.Set up a local sourcing rule for the organization (in this example, Warehouse 1) Type as Transfer from, from the organization that has the stock from which the transfer will take place (example, Warehouse 2).

3.Set up an ATP rule with the Promising Mode as Supply chain availability search.

4.Ensure that the Supply chain availability search attributes are enabled according to your requirements. For example, you might want the application to search components and resources to include on-hand or in-transit Supply Types or fulfillment lines Demand Types.

5.Set the ATP Rule Assignment as required.

6.Set the sourcing assignments for the sourcing rules that you defined in steps 1 and 2.

7.Ensure that the assignment level used for the global sourcing rule doesn't include any Organization.

8.Refresh and restart the Order Promising Server for ATP Rules and Sourcing.

With this setup:

•The global rule is used to source the item from Warehouse 1 if there is stock available to reserve.

•If there's no stock on hand, Global Order Promising uses the local rule to transfer the item from Warehouse 2 to Warehouse 1.

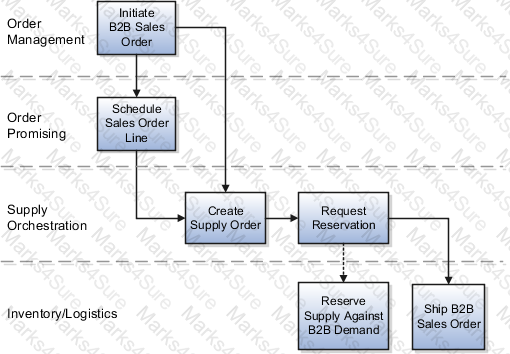

Back-to-Back Supply Creation On-Hand Flow

The back-to-back on-hand available (ATP) flow is the simplest in terms of the number of steps that constitute the flow. This flow occurs where on hand supply is available in the fulfillment warehouse for the ordered back-to-back item at the time of order promising. Because on-hand goods already exist in the form of on hand, Oracle Supply Chain Orchestration directly sends a request to reserve the on hand quantity against the back-to-back sales order. You can ship the sales order immediately after the reservation is created.

The following figure shows the back-to-back supply creation on-hand flow.

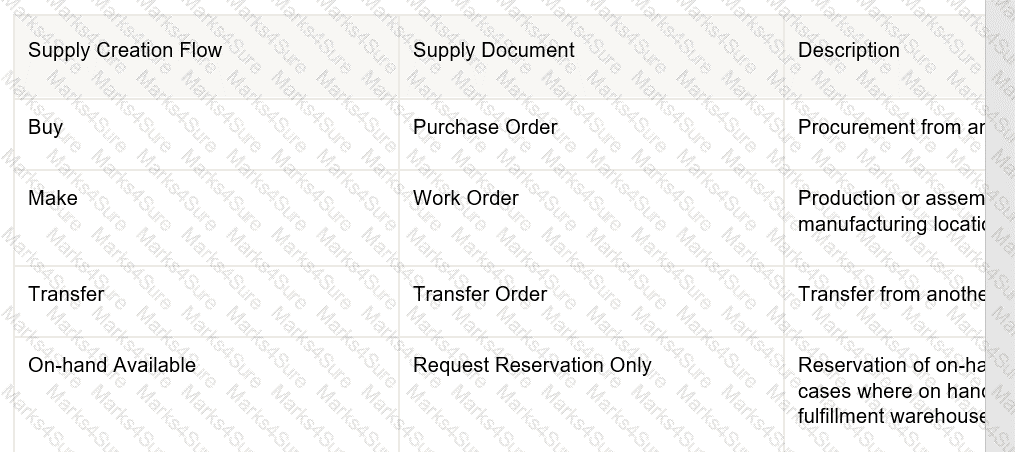

Back-to-Back Supply Creation Flows

You can set up Oracle Fusion Cloud applications that support back-to-back fulfillment to trigger supply creations flows (buy, make, transfer, and on hand) after a sales order is entered and scheduled.

Each variant of the back-to-back flow differs in the supply document that's created and the supply execution application in which the document is created. Depending on the source of the item, supply is provided from manufacturing, procurement, or inventory. Then, after the supply is received into the fulfillment warehouse, the back-to-back order is ready for shipment to your customer.

The following table describes the supply creation flows and associated supply document supported for each flow when using back-to-back fulfillment.

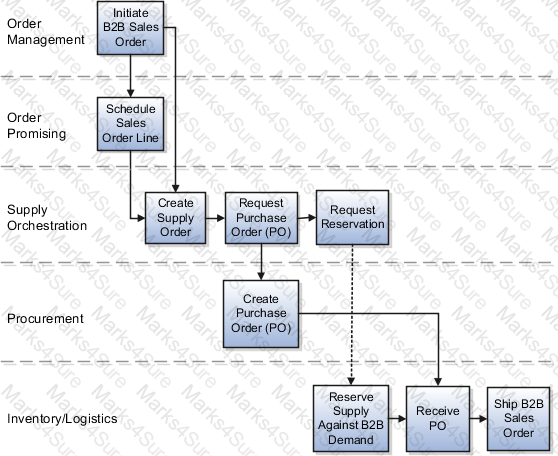

Back-to-Back Supply Creation Buy Flow

The supply document for a back-to-back buy flow is a purchase order. Based on supply recommendations from Oracle Global Order Promising, a purchase order is created and reserved against the sales order. When the purchase order is received by the supplier, on hand is created to ship out the back-to-back sales order.

The following figure shows the back-to-back supply creation buy flow.

The interorganization parameter is not set up completely.Shipment numbers are not generated for transfers using direct organization transfer.Your customer has decided to implement dual UOM tracking for an inventory organization.

Which two statements are FALSE about dual UOM tracking?

What are the functional components of Supply Chain Orchestration? (Choose three)

Your supplier is unable to deliver goods on the promise date against a back-to-back order and updates the promise date on the purchase order schedule to a later date.

How is the change handled on the source side?

What happens when Transfer Order Required is not enabled in the Manage Interorganization Parameters page for Direct Organization Transfer?

You created a consigned agreement with a supplier. The supplier shipped the goods, which you received in your receiving area. After two days, you transferred the goods from receiving into your inventory and used it for your interorganization transfer order.Where is the ownership of the goods?

Steve, your warehouse manager, created a lot for an item by mistake. He is unable to disable this lot from the Manage Lots task.What could be the reason?

Which three sort criteria are available to pick material for a movement request?

Which Orchestration solution can be used to manage Internal Drop Shipments and Revenue Recognition?

Which three statements are true regarding material status control?

You can change the material status at the time the items are received. (*)

Inventory organization M1 has:

Nettable Quantity On-hand = 24

Open Supply Quantity = 51 with all supply within the supply cutoff date

Open Reserved Sales Order Quantity = 90 with all demand within the cutoff date

Open Unreserved Sales Order Quantity = 10

Min-max Minimum Quantity = 100

Min-max Maximum Quantity = 500

Min-max planning report is run for organization level with Yes specified for the Net Reserved Orders parameter.

What will be Total Available Quantity and Reorder Quantity calculated?